Motion Control – Micro-Sized Servo Drives!

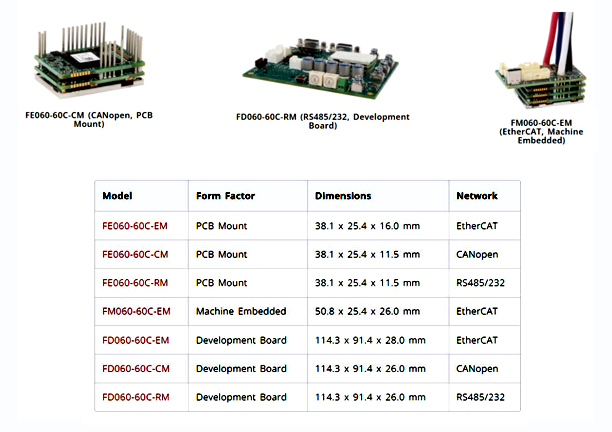

Vaughan, Ontario, Canada — Motion Control Components — ADVANCED Motion Controls has released 7 new micro-sized FlexPro servo drives rated to output 60A continuous. The 60A continuous current rating is 33% higher than previous models for the same size making these our highest power-density servo drives to date. This offering includes PCB Mount, Machine Embedded, and Development Board-factors.

PCB Mount Form Factor

With a footprint of 38.1mm x 25.4mm, up to 4 FlexPro servo drives can fit within the area of a standard business card. The PCB Mount form factor is our most compact configuration with no connectors or housing. They’re intended to be soldered directly to a PCB to help achieve the highest levels of integration.

Machine Embedded Form Factor

These models add a compact interface card to the PCB Mount versions to allow for direct connections with power and signal wires. This form factor makes it easy to install servo drives just about anywhere in a machine.

Development Board Form Factor

Essentially the same as the other models in this product launch but mounted to a larger board populated with full-sized connectors with more spacing in between. Development boards are great for proof-of-concept designs and for setting up experiments on a bench top.

Features:

- EtherCAT, CANopen, RS485/RS232 communication available

- 10-55 VDC input voltage

- Rated for 60A continuous current

- Incremental encoder, EnDat 2.2, and BISS C-mode feedback

- Torque, velocity, and position operating modes

- Very low weight

- Configuration and full loop tuning

- STO (Safe Torque Off)

- IMPACT™ architecture

Projected Industries & Applications:

The small size of the FlexPro® drives makes them perfect for cobots (collaborative robots), AMRs, AGVs, portable devices, lab and warehouse automation, military equipment, and any other integrated design.

About IMPACT™

IMPACT™ (Integrated Motion Platform and Control Technology) is the architecture that makes AMC’s FlexPro® drives possible. The stacking of circuit boards with creative selection and placement of high-power components allows for much higher power density than previously produced servo drives. The expanded processing capabilities ensure the drive’s intelligence is unmatched. IMPACT™ made its debut with FlexPro®. This technology will be used in subsequent FlexPro® drives as well as any future custom products where it is desired.

The full selection of 60Amp FlexPro drives can be found CLICK HERE

The holistic structure of the Electric Encoder™ makes it unique: Its output reading is the averaged outcome of the entire area of the rotor. This feature allows the EE a tolerant mechanical mounting and to deliver outstanding precision.

Due to the absence of components such as ball bearings, flexible couplers, glass discs, light sources and detectors along with very low power consumption enables the EE to deliver virtually failure-free performance in nearly all types of conditions.

The EE output is a digital serial synchronous with absolute position single turn.

This combination of high precision, low profile and, low weight has made Netzer Precision encoders highly reliable and particularly well suited to a wide variety of industrial automation applications.

Information on the VLX-60 Absolute Encoder from Netzer can be viewed at the link below.

About Electromate:

Electromate’s Core Purpose is to help Manufacturers build better machines using differentiated automation technology. They specialize in Robotic and Mechatronic Solutions for the Industrial Automation marketplace. Respected by customers as a premiere source for High Performance Automation and Motion Control Components & Systems, Electromate® specializes in AC & DC Servo and Stepper Motors & Drives, Motion & Automation Controllers, Positioning Systems & Actuators, Feedback Devices, Gearing Products and HMI’s & Operator Displays, all supported via extensive product selection, just-in-timedelivery, dedicated customer service and technical engineering support.

More on Electromate can be found at

Website: http://www.electromate.com

LinkedIn: https://www.linkedin.com/company-beta/209277/

Twitter: https://twitter.com/Electromate

Facebook: https://www.facebook.com/electromateindustrial/

Blog: https://electromate.wordpress.com/

For more information on the “Innovation and Technology Award”

For more information on the “2021 Excellence Award”

For more information on the “Best Place to Work” CLICK HERE!

For more information on the “AHTD Award” CLICK HERE!

To view Electromate’s new corporate video CLICK HERE

For further information on this new product or others in our extensive product portfolio, call 1-877-SERVO99 (737-8699) or e-mail Warren Osak at sales@electromate.com or visit Electromate at: www.electromate.com

See this and other Motion Control Components from Electromate featured on:

http://LinearMotionBlogger.com

http://MotionControlBlogger.com

http://MotionControlBuyersGuide.com

http://Catalogs-MotionControl.com

January 4th, 2022

January 4th, 2022  Editor-Publisher

Editor-Publisher

Posted in

Posted in