AMC Extends the popular DigiFlex® Performancex product line. Their EtherCAT communication servo drives now provides for multiple feedback devices in a variety of power platforms.

|

Greenville, DE —– Motion Control Components – Advanced Motion Controls provides products for the fastest, most flexible form of industrial Ethernet control – EtherCAT®. High speed, deterministic control with standard 100 base-T hardware, EtherCAT Servo Amplifiers are industry proven to achieve blazing fast, consistent results in demanding applications.

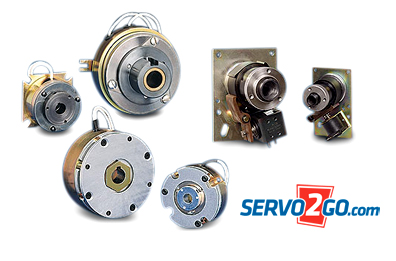

Extending the popular DigiFlex® Performance™ product line our EtherCAT communication servo drives provide for multiple feedback devices in a variety of power platforms. Advanced Motion Controls EtherCAT products consist of panel mount and plug-in servo drives to allow for quick prototyping and ease of system integration. Panel mount DPE drives serve as nodes in single or multi-axis EtherCAT networks, while plug-in DZE/DZS drives utilize AMC’s unique, proprietary high speed multi-axis communication interface and I/O expansion capabilities (‘DxM’™ and ‘DxI/O’™ Technologies). Now a single EtherCAT node can accommodate a combination of up to 4 axes of motion with 32 digital inputs, 32 digital outputs, 4 analog inputs, and 2 analog outputs each. The result is a highly integrated high value motion control solution for single or multi-axis applications.

AMC’s EtherCAT Servo Drives feature:

- Four Quadrant Regenerative Operation

- Space Vector Modulation (SVM) Technology

- Fully Digital State-of-the-art Design

- Programmable Gain Settings

- Fully Configurable Current, Voltage, Velocity and Position Limits

- PIDF Velocity Loop and PID + FF Position Loop

- Compact Size, High Power Density

- 12-bit Analog to Digital Hardware

- Supports Advanced MotionControls’ ‘DxM’ Technology

- On-the-Fly Mode Switching and On-the-Fly Gain Set Switching

More information on the EtherCAT Servo Amplifiers from Advanced Motion Controls available from Servo2Go.com can be viewed at: https://www.electromate.com/advanced-motion-controls.html

These and other Motion Control Products are available through www.Servo2Go.com

For further information on this new product or others in our extensive product portfolio, call 1- 877-378-0240 or e-mail Warren Osak at warren@servo2go.comor visit Servo2Go.com at: www.Servo2Go.com

|

|

|

|

December 28th, 2016

December 28th, 2016  Editor-Publisher

Editor-Publisher